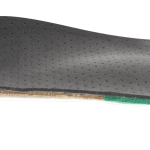

Individual orthopedic, thermally shaped insoles

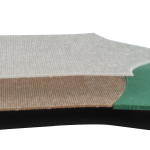

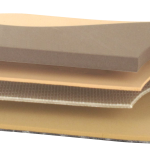

The latest generation of individual orthopedic insoles. They are created from materials of the highest quality, assorted by their properties so as they fulfill their desired purpose. Insoles are shaped under the patient’s foot in order to ensure perfect, individual fitting. The making process includes following steps:

1) Patient stands on silicon pads filled with special granulate

2) Feet placement is corrected in a proper way and then the footprint is embedded via pumping out the air from the silicon pads

3) The bases of orthopedic insoles re heated so as the insoles become malleable

4) Heated insoles are placed on the prepared footprint in the pads and patient stands on them which models the pads after the patient’s feet

5) After few minutes we have insoles which still require some working, the so-called final processing, that is shaping, strengthening of some parts, adding correction – all depending on individual needs

On the video below you can see how such insoles are being made.

Creating such insoles takes from only one hour to three days,

Benefits of individual orthopedic insoles – thermally formed:

- Perfect fitting

- Quick making time

- High durability

- The insoles can be very thin, tht is why they fit most shoes

Prices of individual orthopedic insoles depend their type and size, they range from 125 to 350 PLN

Individual insoles take into account all of the foot-related problems. We can also determine our priorities, which will be our guidelines during the designing process. The functions of running and everyday insoles can be much different. Insoles for ballet flats and bootees can’t look the same. Thus problems experienced by feet as well as lifestyle and needs of the patient are of utmost importance.